A decorative surface treatment of components made of stainless steel and noble materials

It is used especially for following materials:

- STAINLESS STEEL – final surface treatment,

- ALUMINIUM COMPONENTS – before anodic oxidation or coat paining by transparent coat paints,

- OTHER NON-FERROUS METALS – brass, bronze, copper,

- PRE TRETAMENT before galvanization – nickel and chrome painting.

Glass bead blasting process

The best results are reached in a so called two-stage process.

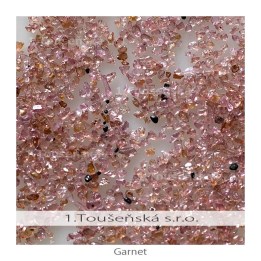

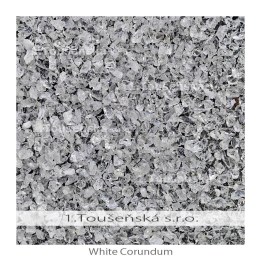

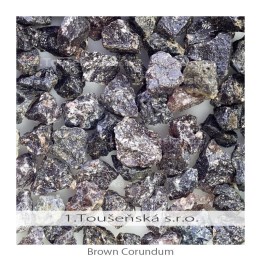

The surface is first treated by sharp-edged abrasives – corundum or garnet. The surface is unified and cleaned from any dirt, oxides, heat tint after welding, and light surface inconsistencies. At this stage treated components gain opaque look.

After the blasting process the surface is prone to scratches or dirt because of the fine sharp-edged relief. This is the reason why the blasting itself is used only as pre-treatment before coat painting. In order to maintain the metal surface, it is polished by glass beads in the second stage of the process. This stage makes the sharp tops of the surface round and products gain nice satin look, which also lowers visibility of any potential damage, scratches, smaller defects after welding, grinding, or spot welding.

Product surface after glass bead blasting is very elegant thanks to the soft, satin look. Simultaneously, it raises product´s corrosion resistance. For subsequent polishing of the surface glass or ceramic beads are used (see examples). Individual materials slightly differ in colour and hardness. They are supplied in a wide range of sizes; therefore, to a great extent it is possible to influence the final appearance of a product.

Blasting media

Mineral abrasives that do not attack the surface of the iron are used for blasting and generally for blasting non-ferrous metals. The abrasive materials are corundum, garnet, or carbides. Glass and ceramic beads are suitable for subsequent polishing.

Examples can be seen in the pictures below. The different materials vary slightly in colour and hardness. They come in a range of sizes and so it is largely possible to influence the final appearance.

Hlavní 91

Lázně Toušeň

250 89

Czechia

ID: 25789066

VAT ID: CZ25789066

YOU MIGHT BE LOOKING FOR...

Glass bead blasting

Gallery

Contact form

CONTACT US

+420 326 995 801

+420 733 770 765

info@1tousenska.cz

the company is registered in the Commercial Register maintained by the Municipal Court in Prague, Section C, File No. 70378, File No. 57186/99